What is the task and scan cycle in codesys?

What is the periodic and cyclic task?

What is a first scan bit?

What is edge detection in codesys?

What is F_Trig and R_Trig in Codesys?

What are DUT and POU in codesys?

What are the differences between timer and counter?

What are the types of timers used in codesys?

What are the types of counters in codesys?

Write a codesys program using Initial Cycle Bit, F_Trig, R_Trig, DUT, POU, and different types of timers and counters.

Write a POU for a main program in plc for motor control.

Write a codesys DUT struct for a motor control system

What is the task and scan cycle in codesys?

In CODESYS, the task and scan cycle are two important concepts related to the execution of a program on a programmable logic controller (PLC). A task is a unit of work that the PLC executes in a fixed cycle time. Each task represents a set of program instructions that the PLC executes repeatedly at a specific rate. For example, a task might control a motor or monitor a sensor. In CODESYS, you can create multiple tasks with different cycle times to execute different parts of your program. On the other hand, the scan cycle is the time it takes for the PLC to complete one iteration of all the tasks in a program. During each scan cycle, the PLC executes each task in turn, based on the task's defined cycle time. Once all the tasks have been executed, the PLC starts a new scan cycle from the beginning. For example, if you have two tasks in your program, one with a cycle time of 10ms and the other with a cycle time of 100ms, the PLC would execute the first task ten times before executing the second task once. This process repeats in a continuous loop, forming the scan cycle. The task and scan cycle are important concepts to understand when programming a PLC in CODESYS, as they help you design and optimize your program's execution flow and performance.

What is the periodic and cyclic task?

In the context of real-time systems, a periodic task is a task that must be executed at a fixed time interval, while a cyclic task is a task that must be executed repeatedly, but not necessarily at a fixed time interval. A periodic task is typically used when a certain operation needs to be executed at a specific rate, such as controlling a motor or reading sensor data. The period of a periodic task is the time interval between two consecutive executions of the task, and it must be constant to ensure the system meets its timing requirements. The execution of a periodic task is triggered by a timer or an external event that occurs at a fixed interval. A cyclic task, on the other hand, is used when a certain operation needs to be executed repeatedly, but not necessarily at a fixed rate. The execution of a cyclic task is triggered by the completion of a previous execution or by an external event that occurs at a non-fixed interval. Cyclic tasks are often used for non-time-critical operations, such as updating the user interface or performing maintenance tasks. In summary, a periodic task must be executed at a fixed time interval, while a cyclic task must be executed repeatedly, but not necessarily at a fixed time interval. Both types of tasks are important in real-time systems, and their use depends on the specific requirements of the system being designed.

What is a first scan bit?

In the context of PLC programming, the "first scan bit" is a special bit that is used to indicate whether the program is running for the first time after being loaded or reset. This bit is often referred to as the "Power-Up Bit" or "Initial Cycle Bit." During the first scan of the PLC program, the first scan bit is set to a value of 1. This allows the program to perform any necessary initialization or setup routines that are required before the program can operate normally. For example, the first scan bit might be used to initialize memory locations, reset counters, or activate certain outputs. After the first scan is complete, the first scan bit is typically reset to a value of 0, and the program enters its normal operating mode. Subsequent scans of the program will not set the first scan bit to 1, as the program is now considered to be running normally. The use of the first scan bit is important because it allows the PLC program to perform any necessary initialization routines before the program starts normal operation. This ensures that the system operates reliably and consistently, even after a power outage or system reset.

What is edge detection in codesys?

In CODESYS, edge detection refers to the ability to detect a transition or change of state on a digital input signal. This transition can be from a low to a high state, or from a high to a low state. Edge detection is often used in industrial automation applications to trigger a specific action or operation when a signal changes state. For example, a sensor might generate a pulse signal when a product passes by on a conveyor belt. The edge detection function can be used to detect each pulse and count the number of products passing by. In CODESYS, edge detection can be implemented using ladder logic or function block diagrams. There are several different types of edge detection functions available, including rising edge detection, falling edge detection, and pulse detection. Rising edge detection is used to detect the transition from a low to a high state on a digital input signal. When a rising edge is detected, a corresponding output signal can be triggered to perform a specific action. Falling edge detection is used to detect the transition from a high to a low state on a digital input signal. When a falling edge is detected, a corresponding output signal can be triggered to perform a specific action. Pulse detection is used to detect the duration of a pulse on a digital input signal. When a pulse is detected, the duration of the pulse can be measured and used to trigger a corresponding output signal. Overall, edge detection is an important feature in CODESYS that allows industrial automation systems to respond to changes in input signals, and perform specific actions or operations based on those changes.

What is F_Trig and R_Trig in Codesys?

F_Trig and R_Trig are two types of edge detection functions available in CODESYS that are used to detect the rising and falling edges of a digital input signal, respectively. F_Trig (short for "positive edge trigger") is an edge detection function that is used to detect the rising edge of a digital input signal. When the input signal transitions from a low state to a high state, the F_Trig function generates a positive output pulse that can be used to trigger a specific action or operation. R_Trig (short for "negative edge trigger") is an edge detection function that is used to detect the falling edge of a digital input signal. When the input signal transitions from a high state to a low state, the R_Trig function generates a negative output pulse that can be used to trigger a specific action or operation. Both F_Trig and R_Trig functions are often used in industrial automation applications to trigger specific actions or operations when a signal changes state. For example, F_Trig might be used to detect the rising edge of a sensor signal indicating the arrival of a product, while R_Trig might be used to detect the falling edge of a signal indicating the departure of the same product. In CODESYS, both F_Trig and R_Trig functions can be easily implemented using ladder logic or function block diagrams and can be customized to meet the specific requirements of a particular application.

What are DUT and POU in codesys?

DUT and POU are two important concepts in CODESYS, which stands for "Device Under Test" and "Program Organization Unit," respectively. DUT refers to the physical device or system that is being tested or controlled using CODESYS. This device can be a PLC, a remote I/O module, a motor controller, or any other type of industrial automation equipment that is capable of communicating with CODESYS. In order to communicate with the DUT, CODESYS must have the appropriate communication interface or driver installed and configured. POU, on the other hand, refers to a logical unit within a CODESYS program that performs a specific function or set of functions. A POU can be thought of as a modular block of code that can be reused across multiple programs, making it easier to develop, test, and maintain complex automation systems. There are several types of POUs available in CODESYS, including: - Function: a POU that performs a specific calculation or operation and returns a value. - Function Block: a POU that performs a specific operation and can have internal variables and inputs/outputs. - Program: a POU that contains a sequence of instructions that are executed in order. - Global Variable List: a POU that defines global variables that can be accessed by other parts of the program. Overall, DUT and POU are two important concepts in CODESYS that are essential for developing and testing industrial automation systems. The ability to communicate with a DUT and to organize code into reusable POUs can significantly improve the efficiency, reliability, and maintainability of a CODESYS program.

What are the differences between a timer and a counter?

In industrial automation and control systems, timers and counters are both commonly used to monitor and control processes, but they serve different purposes and have different functions. Here are the main differences between timers and counters: 1. Function: A timer is used to measure a time interval or delay, while a counter is used to count the number of events or pulses that occur within a certain period of time. 2. Input: A timer usually has a single input, which is typically a signal that triggers the start of the timer. A counter, on the other hand, typically has one or more inputs that are used to count the number of events or pulses. 3. Output: A timer generates an output signal after a specified time interval has elapsed. The output can be used to trigger a specific action or operation, such as turning on a motor or activating a valve. A counter generates an output signal after a certain number of events or pulses have been counted. The output can be used to trigger a specific action or operation based on the count, such as stopping a conveyor belt after a certain number of products have passed through. 4. Types: There are several types of timers available, including on-delay, off-delay, pulse, and cyclic timers, among others. Each type has its own unique features and functions. Counters also come in various types, such as up counters, down counters, and preset counters, among others. 5. Usage: Timers are commonly used in applications where timing is critical, such as in manufacturing processes, traffic control systems, and HVAC systems. Counters are commonly used in applications where counting the number of events or pulses is important, such as in inventory control systems, production line monitoring, and quality control systems. Overall, timers and counters serve different functions and are used in different applications, but both are essential tools for monitoring and controlling industrial processes.

What are the types of timers used in codesys?

CODESYS supports several types of timers, each with its own unique features and functions. Here are some of the most common types of timers used in CODESYS: 1. On-Delay Timer (TON): An On-Delay Timer starts counting time when the input signal turns ON and generates an output signal after a preset time interval has elapsed. 2. Off-Delay Timer (TOF): An Off-Delay Timer starts counting time when the input signal turns OFF and generates an output signal after a preset time interval has elapsed. 3. Pulse Timer (TP): A Pulse Timer generates an output signal that lasts for a preset time interval each time the input signal turns ON. 4. Retentive Timer (TR): A Retentive Timer remembers the time interval that was last counted even after power loss or program restart. This feature is useful in applications where it is important to retain the timer value, such as in tracking machine uptime. 5. Cyclic Timer (TC): A Cyclic Timer generates an output signal that turns ON and OFF at a regular interval. This type of timer is useful in applications where a process needs to be repeated at regular intervals, such as in conveyor belt systems or material handling systems. 6. Watchdog Timer (WD): A Watchdog Timer is used to monitor the status of a program or device and generate an output signal if the program or device fails to respond within a preset time interval. This feature is useful in applications where system failure can have serious consequences, such as in safety-critical systems. Overall, the type of timer used in CODESYS depends on the specific requirements of the application. By choosing the appropriate timer type and configuring it correctly, developers can ensure that the automation system performs the required functions accurately and reliably.

What are the types of counters in codesys?

CODESYS supports several types of counters, each with its own unique features and functions. Here are some of the most common types of counters used in CODESYS: 1. Up Counter (CTU): An Up Counter increments a count value each time the input signal turns ON and generates an output signal when the count value reaches a preset value. 2. Down Counter (CTD): A Down Counter decrements a count value each time the input signal turns ON and generates an output signal when the count value reaches a preset value. 3. Up/Down Counter (CTUD): An Up/Down Counter can count up or down based on the input signal and generates an output signal when the count value reaches a preset value. 4. Ring Counter (CTR): A Ring Counter has multiple output signals that turn ON in a sequence based on the count value. This type of counter is useful in applications where a specific sequence of operations needs to be performed. 5. Shift Register (CTSR): A Shift Register stores a series of input signals in a register and shifts the register contents each time the input signal turns ON. This type of counter is useful in applications where a series of operations needs to be performed sequentially. 6. Pulse Counter (CTP): A Pulse Counter counts the number of input pulses that occur within a preset time interval and generates an output signal when the count value reaches a preset value. Overall, the type of counter used in CODESYS depends on the specific requirements of the application. By choosing the appropriate counter type and configuring it correctly, developers can ensure that the automation system performs the required functions accurately and reliably.

Write a codesys program using Initial Cycle Bit, F_Trig, R_Trig, DUT, POU, and different types of timers and counters.

PROGRAM MainPtogram

VAR InitialCycleBit: BOOL; InputSignal: BOOL; OutputSignal: BOOL; RisingEdge: BOOL; FallingEdge: BOOL; Counter: CTD; Timer: TON; END_VAR (* Program organization unit *) POU CounterReset VAR_INPUT Reset: BOOL; END_VAR VAR_OUTPUT END_VAR VAR InternalCounter: INT; END_VAR IF Reset THEN InternalCounter := 0; ELSE InternalCounter := InternalCounter + 1; END_IF END_POU (* Device under test *) DUT InputProcessing VAR_INPUT Input: BOOL; END_VAR VAR_OUTPUT Output: BOOL; END_VAR VAR RisingEdge: F_TRIG; FallingEdge: R_TRIG; END_VAR (* Rising edge detection *) RisingEdge(CLK := Input, Q => RisingEdge); (* Falling edge detection *) FallingEdge(CLK := Input, Q => FallingEdge); (* Output signal *) Output := RisingEdge.Q; END_DUT (* Main program *) InitialCycleBit := TRUE; Timer(IN := InputSignal, PT := T#10s, Q => OutputSignal); Counter(CU => RisingEdge.Q, CD => FallingEdge.Q, PV => 10, Q => Counter.Q); IF InitialCycleBit THEN (* Initialization code goes here *) InitialCycleBit := FALSE; END_IF (* Reset counter on rising edge of input signal *) CounterReset(Reset := RisingEdge.Q); (* Process input signal *) InputProcessing(Input := InputSignal, Output => OutputSignal); END_PROGRAM

Write a POU for a main program in plc for motor control.

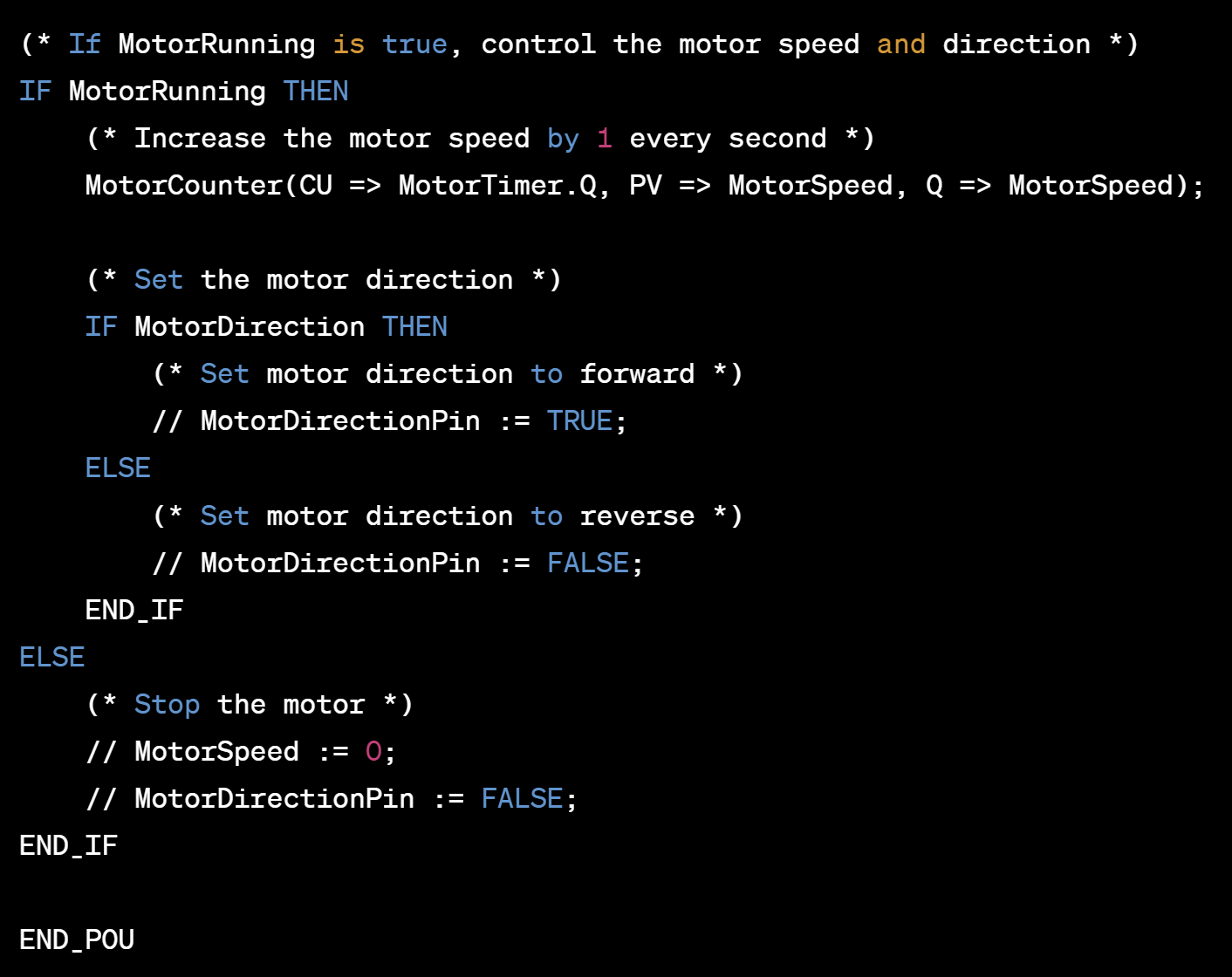

POU MotorControl VAR_INPUT StartMotor: BOOL; StopMotor: BOOL; MotorDirection: BOOL; MotorSpeed: INT; END_VAR VAR_OUTPUT MotorRunning: BOOL; END_VAR VAR MotorTimer: TON; MotorCounter: CTD; END_VAR (* If StartMotor is true and MotorRunning is false, start the motor *) IF StartMotor AND NOT MotorRunning THEN MotorRunning := TRUE; MotorTimer(IN := TRUE, PT := T#5s, Q => MotorRunning); END_IF (* If StopMotor is true and MotorRunning is true, stop the motor *) IF StopMotor AND MotorRunning THEN MotorRunning := FALSE; END_IF (* If MotorRunning is true, control the motor speed and direction *) IF MotorRunning THEN (* Increase the motor speed by 1 every second *) MotorCounter(CU => MotorTimer.Q, PV => MotorSpeed, Q => MotorSpeed); (* Set the motor direction *) IF MotorDirection THEN (* Set motor direction to forward *) // MotorDirectionPin := TRUE; ELSE (* Set motor direction to reverse *) // MotorDirectionPin := FALSE; END_IF ELSE (* Stop the motor *) // MotorSpeed := 0; // MotorDirectionPin := FALSE; END_IF END_POU

In this POU, there are four inputs:

- StartMotor: A boolean input that starts the motor when set to TRUE.

- StopMotor: A boolean input that stops the motor when set to TRUE.

- MotorDirection: A boolean input that sets the direction of the motor. If TRUE, the motor spins in one direction, and if FALSE, it spins in the opposite direction.

- MotorSpeed: An integer input that sets the speed of the motor.

There is one output:

- MotorRunning: A boolean output that indicates whether the motor is currently running or not.

The POU also contains two internal variables:

- MotorTimer: A timer that counts for 5 seconds when the motor is started. After 5 seconds, if the timer has not been reset, it sets MotorRunning to FALSE.

- MotorCounter: A counter that increments the MotorSpeed value by 1 every second while the motor is running.

The POU contains three main sections:

Start/Stop Logic: This section starts or stops the motor based on the inputs. If StartMotor is set to TRUE and MotorRunning is set to FALSE, the motor is started and MotorRunning is set to TRUE. If StopMotor is set to TRUE and MotorRunning is set to TRUE, the motor is stopped, and MotorRunning is set to FALSE.

Motor Speed and Direction: This section controls the speed and direction of the motor while it is running. If MotorRunning is set to TRUE, the MotorCounter increments the MotorSpeed value by 1 every second. The MotorDirection input sets the direction of the motor based on whether it is TRUE or FALSE.

Stop Timer: This section stops the motor after 5 seconds if the MotorTimer has not been reset. If MotorRunning is set to TRUE, the MotorTimer is reset, and the timer starts counting again. If the MotorTimer reaches 5 seconds and is not reset, it sets MotorRunning to FALSE, which stops the motor.

Again, this is just an example, and you may need to modify it based on your specific motor control application.

Write a codesys DUT struct for a motor control system

// Define a DUT struct for the motor control system // This struct contains inputs, outputs, and internal variables for the system DUT MotorControlSystem: STRUCT // Inputs StartMotor: BOOL; StopMotor: BOOL; MotorDirection: BOOL; MotorSpeed: INT; // Outputs MotorRunning: BOOL; // Internal variables MotorTimer: TON; MotorCounter: CTD; END_STRUCT

In this DUT struct, there are four inputs:

- StartMotor: A boolean input that starts the motor when set to TRUE.

- StopMotor: A boolean input that stops the motor when set to TRUE.

- MotorDirection: A boolean input that sets the direction of the motor. If TRUE, the motor spins in one direction, and if FALSE, it spins in the opposite direction.

- MotorSpeed: An integer input that sets the speed of the motor.

There is one output:

- MotorRunning: A boolean output that indicates whether the motor is currently running or not.

The DUT struct also contains two internal variables:

- MotorTimer: A timer that counts for 5 seconds when the motor is started. After 5 seconds, if the timer has not been reset, it sets MotorRunning to FALSE.

- MotorCounter: A counter that increments the MotorSpeed value by 1 every second while the motor is running.

You can use this DUT struct as a blueprint for implementing the motor control system in your CODESYS project.

No comments:

Post a Comment